Generators are essential machines that provide backup power in homes, industries, hospitals, and more. Whether you're relying on them for emergency power or as a continuous source of electricity in remote locations, ensuring your generator has a long and efficient lifespan is crucial. A well-maintained generator can serve you reliably for years, reducing the need for frequent repairs and replacements. In this comprehensive guide, we will explore practical ways to increase your generator's lifespan, focusing on best practices, maintenance tips, and expert recommendations.

Understanding the Role of Diesel Engines in Modern Applications

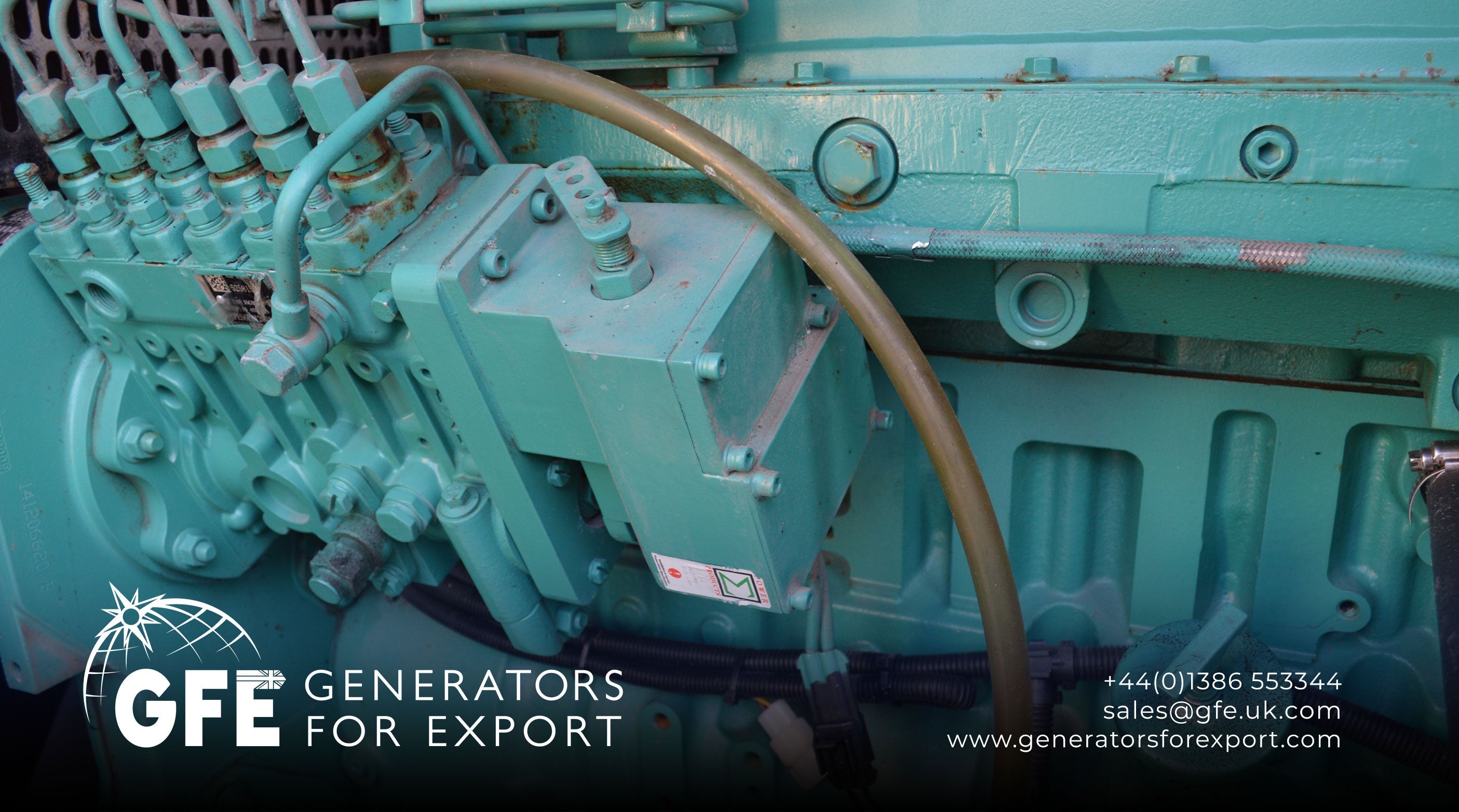

Before diving into how to enhance the lifespan of your generator, it's important to understand the role diesel engines play in various industries. Diesel engines power most industrial and backup generators due to their reliability, durability, and performance.

Diesel Engines in Transportation

Diesel engines are widely used in commercial vehicles, such as trucks, buses, and ships. These engines are known for their efficiency in moving heavy loads over long distances. Diesel-powered vehicles can sustain high levels of power output for extended periods, making them ideal for the transportation industry.

When looking at generators, the diesel engine's efficiency and capability to handle large loads are just as crucial. This is why many backup and industrial generators are powered by diesel engines. They provide a consistent power source, especially in areas where reliable electricity is essential, like in remote regions or during power outages.

Diesel Engines in Power Generation

In power generation, diesel engines play a pivotal role in ensuring continuous power supply. Diesel-powered backup generators are essential for homes, hospitals, and industrial facilities, especially in locations where the electricity grid is unreliable or non-existent. Their efficiency and reliability make them an indispensable resource, particularly in emergencies.

If you are considering enhancing your generator's lifespan, understanding the role of its diesel engine is essential. Diesel engines are designed to endure prolonged operation, which makes them excellent for backup power applications. They can deliver consistent performance even when subjected to heavy loads.

Diesel Engines in Agriculture and Construction

Diesel engines are also commonly used in heavy machinery, such as tractors, excavators, and other construction equipment. These engines are vital in ensuring uninterrupted work in critical sectors like agriculture and construction, where downtime can lead to substantial financial losses.

Generators in these industries need to be reliable, as they are often used in remote areas where access to repairs is limited. Ensuring proper maintenance and regular servicing can significantly contribute to a generator’s longevity, preventing costly breakdowns when they are most needed.

Advantages of Diesel Engines: Why They Are Ideal for Generators

Generators powered by diesel engines have several inherent advantages, including fuel efficiency, durability, and performance. These qualities make them the preferred choice for backup and primary power generation in various applications.

Fuel Efficiency and Cost-Effectiveness

One of the most significant advantages of diesel-powered generators is their fuel efficiency. Diesel engines are more fuel-efficient than their petrol counterparts, making them cost-effective in the long run. Diesel engines consume less fuel to produce the same amount of energy, which can result in significant savings over time, especially for large-scale operations or homes relying on generators for extended periods.

By choosing a high-efficiency diesel generator and following proper maintenance practices, you can make your generator last longer and run at optimal fuel efficiency. Regular maintenance, such as changing air and fuel filters, is essential to maintaining fuel efficiency.

Durability and Longevity

Diesel engines are known for their robust design and ability to withstand high workloads. Unlike petrol engines, which are generally less durable, diesel engines are built to last. They are capable of handling tough working conditions and can run for thousands of hours before requiring major repairs.

By ensuring that your diesel-powered generator receives the necessary care, you can greatly increase its lifespan. Regular checks on engine oil levels, coolant, and the condition of critical components such as belts and hoses can prevent premature wear and tear, allowing your generator to perform optimally for years.

High Torque and Performance

Diesel engines are designed to provide high torque, making them ideal for heavy-duty tasks such as powering large generators. Diesel engines perform consistently under load, ensuring that your generator will deliver uninterrupted power even when operating under high-demand conditions.

If you aim to increase your generator's lifespan, ensure that the engine runs at its optimal performance levels. This involves monitoring load conditions and avoiding overloading the generator, which can cause strain on the engine, reducing its operational lifespan.

Environmental and Technological Considerations in Generator Maintenance

As the world shifts toward more sustainable practices, modern diesel engines are being adapted to meet environmental standards while maintaining their performance. Technological advancements have led to cleaner-burning diesel engines, which produce fewer emissions and are more energy-efficient than older models.

Modern Diesel Engines and Emissions

Today’s diesel engines are equipped with advanced emission control technologies such as exhaust after-treatment systems and selective catalytic reduction (SCR). These technologies help reduce harmful emissions, making diesel generators more environmentally friendly and compliant with stricter emission regulations.

To ensure that your diesel-powered generator operates efficiently and lasts longer, it is important to choose a model that meets current emission standards. This is particularly important if your generator is used in regions with stringent environmental regulations.

Alternative Diesel Fuels

Another way to increase the lifespan of your generator while reducing its environmental impact is by using alternative diesel fuels. Biodiesel and renewable diesel are two options that offer a sustainable alternative to traditional diesel. These fuels are produced from renewable resources and can significantly reduce greenhouse gas emissions.

When using alternative fuels, it is important to check your generator’s compatibility. Some diesel engines may require specific modifications to operate efficiently on biodiesel or renewable diesel. By opting for these fuels, you contribute to a more sustainable operation while maintaining your generator’s longevity.

Why Diesel Engines Remain Relevant in Power Generation Today

Despite the growing popularity of renewable energy sources, diesel engines continue to play a critical role in power generation. Their efficiency, reliability, and versatility make them indispensable for a wide range of applications, from backup power systems to heavy-duty machinery.

Global Dependency on Diesel

Diesel remains the dominant fuel for backup power generation worldwide. It is particularly important in industries and regions where uninterrupted power supply is essential. Logistics, mining, and emergency services are just a few sectors that rely heavily on diesel-powered generators to ensure business continuity.

If you are looking to make your diesel generator last longer, it is important to remember that regular maintenance and timely servicing are essential for ensuring that your generator performs optimally for years to come. Diesel-powered generators are durable and designed for longevity, but only if they are well-maintained.

Balancing Efficiency and Innovation

With the continuous evolution of energy technologies, diesel engines are adapting to work in tandem with hybrid systems and renewable energy sources. The integration of solar power, wind energy, and battery storage with diesel generators is becoming more common, creating a hybrid power system that offers the best of both worlds.

Diesel generators are also increasingly being used in conjunction with renewable energy solutions, providing backup power when needed and reducing overall fuel consumption. By embracing technological advancements and integrating your generator with renewable energy systems, you can reduce the strain on your diesel engine and enhance its lifespan.

Best Practices for Increasing Generator Lifespan

Now that we’ve explored the advantages of diesel engines and their role in power generation, let’s focus on practical steps you can take to increase the lifespan of your generator. Proper maintenance is essential to ensure that your generator operates efficiently for as long as possible.

- Regular Maintenance Checks: Regular maintenance is key to ensuring your generator remains in top condition. Perform routine checks on essential components such as the engine oil, fuel filters, and air filters. Regularly check the radiator and coolant levels to prevent overheating. A thorough inspection will help identify any potential issues before they become major problems.

- Prevent Overloading: One of the quickest ways to shorten your generator’s lifespan is by overloading it. Make sure that your generator is operating within its capacity, as exceeding its limits can cause significant damage to the engine. Always monitor the load to ensure your generator is working efficiently. Learn more about generator damage from running on low load.

- Use Quality Fuel: The type of fuel you use plays a crucial role in your generator’s longevity. Always use high-quality, clean diesel fuel to prevent contamination and clogging of engine components. Regularly check for signs of fuel degradation and ensure that your generator is running on fresh fuel. For more information on preserving the quality of stored diesel, read our recent blog article.

- Store Your Generator Properly: If your generator is not in constant use, proper storage is essential to prevent damage. Ensure that the generator is stored in a clean, dry environment away from extreme temperatures. If you are storing the generator for an extended period, follow the manufacturer’s guidelines for winterisation to prevent corrosion and engine degradation.

- Use the Generator Regularly: Generators that are not used regularly may develop issues over time, including fuel system clogs and battery problems. Run your generator periodically to keep it in good working condition, even if you don’t need it for power generation. Regular use helps keep the components in top shape and ensures that the engine stays lubricated.

- Hire a Professional for Routine Servicing: Although some maintenance tasks can be handled by the owner, certain complex issues require professional expertise. Schedule routine servicing with a qualified technician who can perform in-depth diagnostics, address minor issues, and ensure that your generator is operating at peak efficiency.

Increasing the lifespan of your diesel generator is achievable through regular maintenance, proper usage, and timely servicing. By understanding the role of diesel engines, embracing technological advancements, and following best practices for maintenance, you can ensure that your generator serves you reliably for years to come. Whether you're using it for backup power or industrial applications, a well-maintained generator will continue to perform when you need it most, saving you money and reducing the likelihood of unexpected repairs.

For more information on generator maintenance and decommissioning, be sure to check out our related articles, including How Do I Choose The Right Used Generator and Why Should I Service My Generator/Engine.

Call: +44(0)1386 553344 | Email: sales@gfe.uk.com